Introduction

Why is washing machine repair important?

Washing machine repair is important for several reasons. First and foremost, it can save you a significant amount of money. Instead of buying a new washing machine when it breaks down, repairing it can be a much more cost-effective option. Additionally, repairing your washing machine helps to extend its lifespan, allowing you to get more use out of it before needing to replace it. Furthermore, regular maintenance and repairs can prevent small issues from turning into major problems, ultimately saving you time and hassle. Lastly, repairing your washing machine is also an environmentally friendly choice, as it reduces electronic waste. Overall, taking care of your washing machine and promptly addressing any repair needs is crucial for its longevity and your convenience.Common washing machine problems

Washing machines are an essential appliance in many households, but they can experience common problems that may require repair. One common issue is a washing machine that won’t start. This could be due to a faulty power cord, a malfunctioning control panel, or a problem with the door switch. Another common problem is a washing machine that doesn’t drain properly. This could be caused by a clogged drain hose, a malfunctioning pump, or a problem with the drain filter. Lastly, a common issue is a washing machine that doesn’t spin or agitate. This could be due to a worn-out drive belt, a faulty motor, or a problem with the lid switch. If you’re experiencing any of these problems with your washing machine, it’s important to seek professional repair help to ensure proper functioning and avoid further damage.Benefits of DIY washing machine repair

There are several benefits to DIY washing machine repair. First and foremost, it can save you a significant amount of money. Hiring a professional repair service can be expensive, but by taking on the repairs yourself, you can avoid these costs. Additionally, repairing your washing machine on your own gives you a sense of accomplishment and self-reliance. It allows you to take control of the situation and solve the problem at hand. Furthermore, DIY repairs can often be done quickly and conveniently, without the need to wait for a technician to arrive. Overall, opting to repair your washing machine yourself can be a cost-effective, empowering, and efficient solution.Basic Troubleshooting

Checking power supply

When it comes to checking the power supply of a washing machine, there are a few key steps you can take. First, make sure the machine is plugged in and the power switch is turned on. If the machine still doesn’t turn on, check the circuit breaker to see if it has tripped. If the circuit breaker is fine, you may need to test the outlet with a multimeter to ensure it is receiving power. Additionally, inspect the power cord for any signs of damage or fraying. If all else fails, it may be necessary to call a professional technician to further diagnose and repair the power supply issue.Examining water supply

When examining water supply for washing machine repair, it is important to check for any leaks or blockages in the water hoses. Inspect the water inlet valve to ensure it is functioning properly and not clogged with debris. Additionally, check the water pressure to ensure it is within the recommended range for the washing machine. If any issues are found during the examination, it is recommended to consult a professional for further assistance.Inspecting drainage system

When inspecting the drainage system of a washing machine, it is important to check for any clogs or blockages. Start by disconnecting the machine from the power source and removing the drain hose. Carefully inspect the hose for any debris or buildup that may be causing the drainage issue. If necessary, use a brush or pipe cleaner to remove any obstructions. Additionally, check the drain pump for any clogs or damage. If the pump is clogged, it may need to be cleaned or replaced. Finally, ensure that the drain pipe is properly connected and free from any blockages. By thoroughly inspecting the drainage system, you can identify and resolve any issues that may be affecting the performance of your washing machine.Cleaning and Maintenance

Cleaning the drum

Cleaning the drum of your washing machine is an essential step in maintaining its performance and prolonging its lifespan. Over time, dirt, grime, and detergent residue can build up inside the drum, leading to unpleasant odors and potentially affecting the cleanliness of your clothes. To clean the drum, start by removing any visible debris or lint. Then, mix a solution of warm water and mild detergent and use a soft cloth or sponge to wipe down the interior surfaces. Pay special attention to the rubber seal and any hard-to-reach areas. Finally, run an empty cycle with hot water and vinegar to further remove any remaining residue. Regularly cleaning the drum will ensure that your washing machine continues to operate efficiently and effectively.Removing lint and debris

Lint and debris can accumulate in your washing machine over time, causing it to function less efficiently. To remove lint and debris, start by unplugging the machine and pulling it away from the wall. Then, remove the lint filter and clean it thoroughly. Use a vacuum cleaner or a soft brush to clean the drum and the gasket. Additionally, check the drain hose for any clogs or blockages and clear them if necessary. Regularly removing lint and debris from your washing machine will help it run smoothly and prolong its lifespan.Cleaning the detergent dispenser

Cleaning the detergent dispenser is an essential step in maintaining the performance and longevity of your washing machine. Over time, residue from laundry detergents and fabric softeners can build up in the dispenser, leading to clogs and reduced cleaning efficiency. To clean the detergent dispenser, start by removing it from the washing machine. Then, rinse it thoroughly with warm water to remove any leftover detergent or fabric softener. Use a small brush or toothbrush to scrub away any stubborn residue. Once the dispenser is clean, dry it completely before placing it back into the washing machine. Regularly cleaning the detergent dispenser not only ensures optimal cleaning results but also helps prevent unpleasant odors and mold growth. Make it a part of your regular washing machine maintenance routine for hassle-free laundry days.Replacing Parts

Replacing the water inlet valve

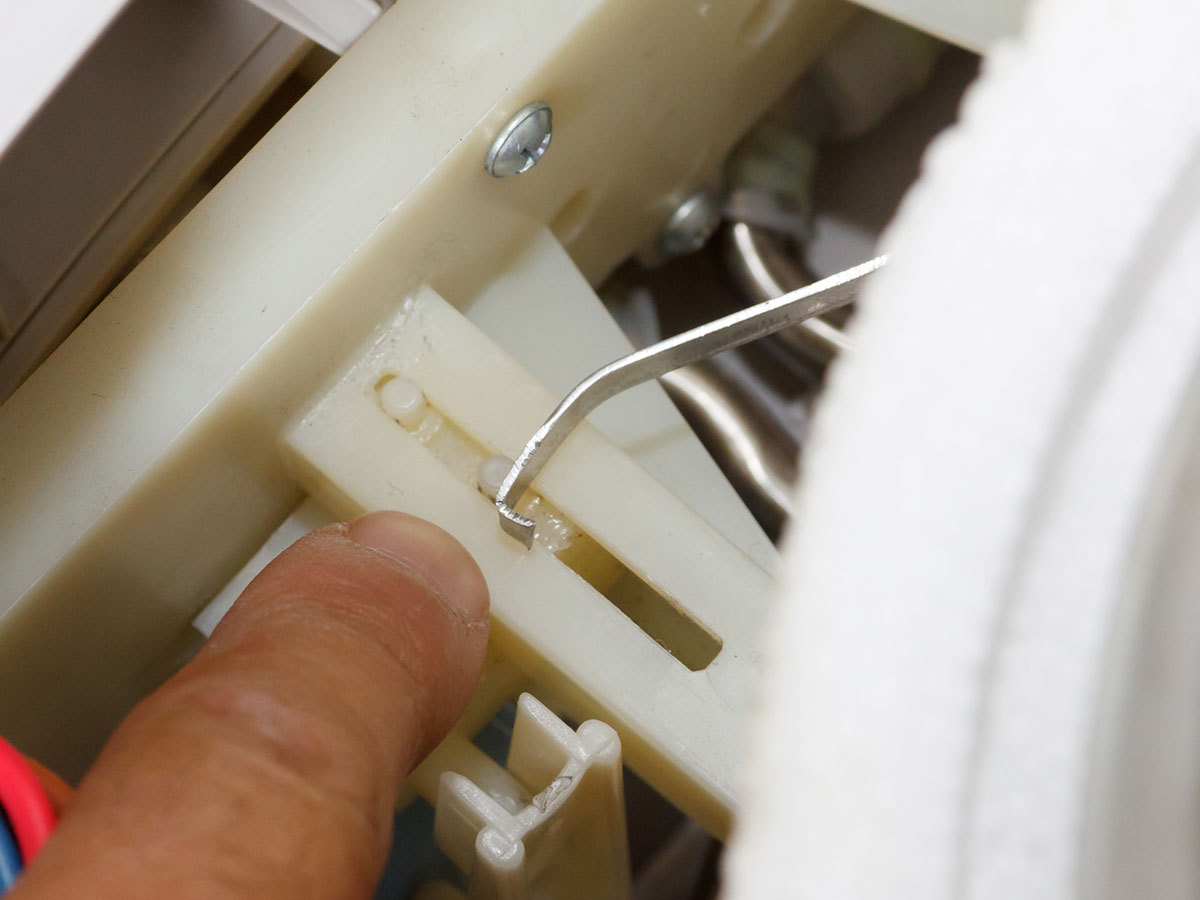

Replacing the water inlet valve is an essential step in washing machine repair. The water inlet valve controls the flow of water into the machine, and if it is faulty or damaged, it can lead to issues such as low water pressure or no water at all. To replace the water inlet valve, you will need to disconnect the power and water supply to the machine. Then, remove the top or back panel of the washing machine to access the valve. Carefully disconnect the electrical connections and water hoses connected to the valve. Once the old valve is removed, install the new valve by reversing the steps. Make sure to securely connect the electrical and water connections. Finally, test the machine to ensure that the new water inlet valve is functioning properly. Replacing the water inlet valve can help restore the proper functioning of your washing machine and prevent further damage.Replacing the drain pump

Replacing the drain pump in a washing machine is a common repair task that can be done by most homeowners. The drain pump is responsible for removing water from the machine during the drain cycle. Over time, the pump may become clogged or damaged, resulting in poor drainage or no drainage at all. To replace the drain pump, you will need to first disconnect the power and water supply to the machine. Then, locate the drain pump, which is usually located at the bottom of the machine. Remove any screws or clips holding the pump in place and disconnect the wiring harness. Install the new drain pump by reversing the steps and make sure it is securely in place. Finally, test the machine to ensure proper drainage. If you are unsure about any step of the process, it is recommended to consult the washing machine’s manual or seek professional help.Replacing the door seal

Replacing the door seal in a washing machine is a common repair task that can help restore the efficiency and performance of the appliance. Over time, the door seal may wear out or become damaged, leading to leaks or ineffective sealing. To replace the door seal, first, make sure to disconnect the power supply to the washing machine. Then, carefully remove the old seal by loosening the retaining clamp or screws. Clean the area thoroughly to remove any debris or residue. Next, install the new door seal by aligning it properly and securing it with the retaining clamp or screws. Finally, reconnect the power supply and test the washing machine to ensure the door seal is working effectively. Replacing the door seal can extend the lifespan of your washing machine and prevent further damage or leaks.Common Issues and Solutions

Washing machine not spinning

If your washing machine is not spinning, it could be due to a number of reasons. One possibility is a problem with the motor or belt that drives the spinning motion. In this case, you may need to replace the motor or belt to restore proper functionality. Another possible cause could be a blockage in the drain pump or filter, preventing the water from draining properly and causing the machine to not spin. Cleaning or replacing the drain pump or filter may be necessary in such cases. Additionally, an unbalanced load of laundry can also prevent the machine from spinning. Make sure to distribute the clothes evenly in the drum to avoid this issue. If none of these solutions work, it is recommended to seek professional help to diagnose and fix the problem.Water not draining properly

If you are experiencing the issue of water not draining properly in your washing machine, there are a few possible causes to consider. Firstly, check if there is any blockage in the drain hose or the pump filter. These can become clogged with lint, debris, or small objects, preventing proper water drainage. Additionally, a malfunctioning pump or a faulty drain valve could also be the culprit. In some cases, the problem may be related to an imbalance in the load, causing the water to not drain effectively. It is recommended to inspect and clean the drain hose, pump filter, and other components regularly to ensure smooth water drainage and prevent any potential issues. If the problem persists, it is advisable to seek professional help to diagnose and repair the underlying cause of the water not draining properly in your washing machine.Machine making strange noises

If your washing machine is making strange noises, it could be a sign of a potential problem. There are several reasons why your machine may be making these noises, such as a loose belt, worn-out bearings, or a malfunctioning motor. It is important to address these strange noises as soon as possible to prevent further damage to your washing machine. Contact a professional repair service to diagnose and fix the issue, ensuring that your machine operates smoothly and quietly once again.Safety Precautions

Disconnecting power supply

Disconnecting the power supply is an essential step when it comes to repairing a washing machine. This ensures the safety of the person working on the appliance and prevents any electrical accidents. To disconnect the power supply, start by unplugging the washing machine from the electrical outlet. If the outlet is not easily accessible, switch off the circuit breaker that supplies power to the washing machine. It is important to double-check that the power is completely disconnected before proceeding with any repair work. Taking this precautionary measure will help to avoid any potential risks and ensure a smooth and safe repair process.Using protective gear

When it comes to using protective gear during washing machine repairs, safety should always be the top priority. Wearing the right gear not only helps prevent accidents but also protects you from potential hazards. Some essential protective gear to consider includes safety goggles to shield your eyes from debris, gloves to protect your hands from sharp edges or chemicals, and a face mask to prevent inhaling dust or fumes. Additionally, wearing non-slip shoes can help prevent slips and falls while working. By using the appropriate protective gear, you can ensure a safe and successful washing machine repair experience.Avoiding electrical hazards

When it comes to avoiding electrical hazards while repairing a washing machine, there are a few important precautions to keep in mind. Firstly, always make sure to unplug the machine from the power source before beginning any repairs. This will help prevent any accidental electric shocks. Additionally, it is crucial to wear protective gloves and other safety gear to minimize the risk of injury. It is also advisable to have a basic understanding of electrical circuits and wiring to ensure safe handling of the machine. Finally, if you are unsure or uncomfortable with any electrical repairs, it is best to seek professional help to avoid any potential hazards.Getting high quality professional help in repairing Washing Machines nowadays is quite difficult, I have decided to standardize the procedures in order to provide the client with the highest quality of work that would exceed the expectations if not just match it.

Click Here to get in touch with us If you have any questions: Email us Thank you for voting for us as the Best Washing Machine Repair company in UAE If you are looking for Tools to use, These are our recommendations

I am an Engineer who is very interested in building a platform that ensures highest standards of quality to be maintained in all forms of maintenanc services and the unification of them in a seemless way.